Before the internet and the digital age, portable devices like mobile phones, “still” and “video” cameras, videogame players, word processors, and even flashlights were bulky and heavy. Usability for devices with rechargeable batteries was generally less than half an hour. The rest of those devices required an endless stream of single-use batteries or constant power from wall sockets while in use. As consumers began to bring more of their devices “on-the-go,” portability without constraints became more important. And naturally, increasingly power-hungry product performance escalated the appetite for smaller yet powerful rechargeable batteries.

Over the past few decades, lithium-ion and more recent chemistries including silicon have enabled manufacturers to conceptualize new advancements in battery-powered applications. The growth of the silicon battery market continues to push the goalpost for performance and capabilities, setting a new standard for rechargeable batteries.

In the second part of our series, we’ll explore the two most notable innovations that followed the Nickel-metal Hydride battery: lithium-ion and silicon batteries, which have kindled and accelerated innovation over the last few decades.

The catalyst for connected lives

The commercialization of the modern-day lithium-ion battery culminated from the work of many researchers around the globe, three of whom were credited with a Nobel Prize: M. Stanley Whittingham, John B. Goodenough, and Akira Yoshino. In the 1970s, M. Stanley Whittingham became obsessed with the idea of a lithium-based rechargeable battery during his time at Exxon Mobil. He experimented with a few iterations including lithium metal, but the project was ultimately scrapped due to safety concerns.

From there, Professor John B. Goodenough tinkered with the chemistry, swapping out titanium disulfide for lithium cobalt oxide in the cathode, immediately seeing a boost in energy density. This critical change became a significant turning point for the battery, setting the stage for chemist Akira Yoshino to experiment with replacing lithium metal with lithium ions to create the first iteration of the stable, lightweight lithium-ion battery as we know it today.

It didn’t take long for consumers in the 1990s to adopt lithium-ion as the go-to battery chemistry. Lithium-ion batteries were instrumental in transforming bulky, stationary desktop computers into slimmer laptops and corded phones into the smartphones in our pockets today. In 1991, Sony launched the first lithium-ion battery, initially used for the Sony CCD-TR1 8mm camcorder. After receiving rave reviews, other battery manufacturers began to hop on the bandwagon, which marked the beginning of the world’s dependence on lithium-ion as an energy storage solution. Today, lithium-ion still powers many of our electronically enabled devices and vehicles including laptops, smartphones, e-bikes and more.

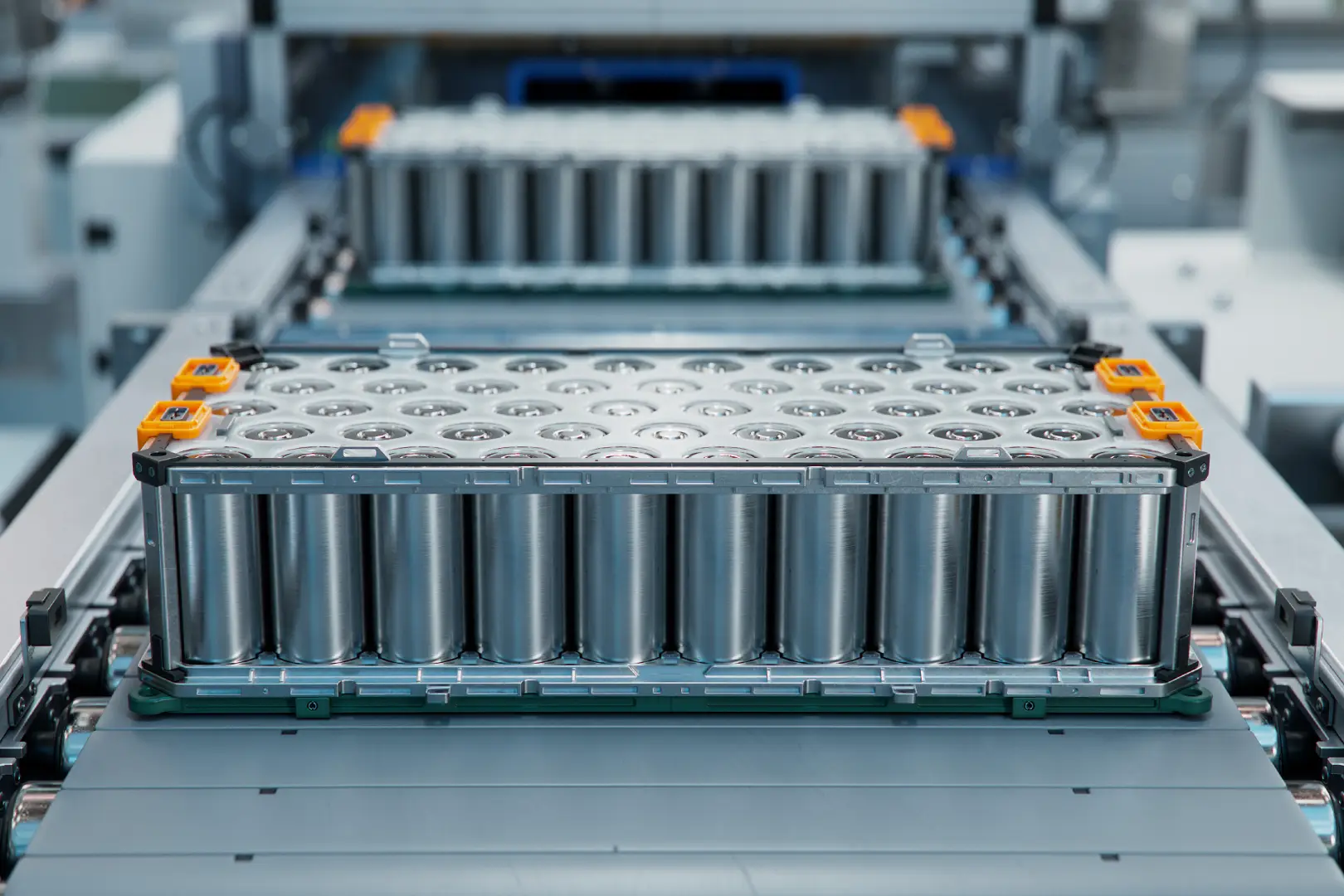

Boasting performance far beyond those of the lead-acid, NiCd and NiMH batteries we covered in Part 1, lithium-ion batteries deliver greater energy density in a broad range of smaller formats. Throughout the 1990s and 2000s, lithium-ion batteries enabled exponential energy advancements, but are increasingly falling short in the face of today’s energy-intensive demands. Over the last decade, the industry has voiced a growing desire for more power and portability. Before, improvements in battery performance and device capabilities were non-essential conveniences. Now, with increasingly high dependence on AI applications, devices with longer battery life and faster charging are features we can’t live without.

Lithium-ion’s evolution from graphite to silicon

While lithium-ion battery chemistries typically include a graphite anode, the first instance of a lithium battery using silicon as an anode material was reported by General Motors in 1976 – almost a decade before the first graphite anode. Yet for years, silicon came second to graphite, as the material presented two major challenges: its tendency for expansion and more limited use in high-temperature batteries.

As lithium-ion battery performance plateaued in the early 2000s, the industry began to re-examine the commercial viability of silicon. Compared to standard lithium-ion batteries, silicon batteries carry far more lithium ions in the anode, demonstrating even more energy density, greater reliability and the ability to fast-charge in minutes – or in some cases, flash-charge within seconds.

Take today’s white-collar workforce, many of which transitioned to remote work at the onset of the pandemic. With limited space at home, traditional office workers began to spend time working at cafes, vying for seats next to power outlets to keep plugged in throughout the day. With the rise in hybrid and remote positions, the stakes for better-performing, longer-lasting devices have never been higher. Enabling consumers to live unplugged lives, silicon-powered rechargeable batteries could make cumbersome cords obsolete.

Silicon’s incredible potential also goes both ways to enable fast discharging as well. Critical infrastructure including battery energy storage systems (BESS), which help relieve strain on data centers and the grid as well as mitigating the intermittency of solar and wind generation, are also in line to benefit greatly from silicon batteries. As the growth of AI and data centers leads to unprecedented load growth, silicon batteries will be a go-to solution for round-the-clock power.

Powering the future with silicon

Compared to the slow-and-steady pace of innovation during the turn of the 20th century, today, companies are designing, manufacturing and delivering new products at a fast clip. Energy storage remains one of the key components enabling the growth of many industries – from EVs to AI and more. Leapfrogging over the stagnant performance of lithium-ion batteries, silicon batteries have emerged as the technology enabling new possibilities. From super-charging smartphones to buoying the rapid emergence of data centers, silicon is the long-sought solution for today’s and tomorrow’s energy needs.

To learn more about our own journey in developing and commercializing our flagship silicon battery technology SCC55, check out The Story of Group14 Technologies: The Journey to the Electrification of Everything.