The Electrification of Everything

In April 2021, we announced commercial manufacturing had begun for our drop-in ready flagship silicon-carbon composite anode material, SCC55™, at the world’s first BAM factory (Battery Active Materials factory) of its kind. Since the announcement, we’ve seen incredible industry enthusiasm related to the potential of this new lithium-silicon battery technology and the impact it will have on electric vehicles (EVs), electronics, aerospace, grid storage, and other battery applications.

The introduction of a new battery technology that can help usher in the electrification of everything creates differing perspectives and even misunderstandings. This paper intends to help stakeholders and customers better understand the broader battery landscape and where Group14 and our silicon-based anode technology falls within it.

Key Terms For Assessing Battery Desirability

The following key terms are often used to help energy storage industry experts assess the viability of new lithium battery technologies and will be used throughout this paper.

- We call the storage or potential energy discharge of lithium ions a battery’s Energy Density.

- The first time a new battery is charged, some of the lithium is permanently consumed in formation reactions. We call the percentage of lithium that remains available for future use, First Cycle Efficiency.

- And we call a battery’s recharging lifespan Battery Cycle Life.

While several variables determine battery and battery material desirability, namely performance, price, scalability, and ability to “drop-in” to existing battery manufacturing processes, the above three performance measurements must be dramatically improved for next-generation batteries to be market viable. These improvements coupled with manufacturability will enable the rapid transition of the industry toward the electrification of everything.

Demand for the Electrification of Everything

“Global energy demand is anticipated to skyrocket by upwards of 58% over the next three decades” (van Ruijven, B.J., De Cian, E. & Sue Wing, I. Amplification of future energy demand growth due to climate change. Nature Communications 10, 2762 [2019]). Fossil fuels can no longer accommodate the demand nor are they sustainable for our environment. The urgency to transition beyond fossil fuels for energy consumption is now a necessity. The response to this demand is simple: electrify everything with renewable energy sources and through battery power. Unfortunately, clean energy sources are typically naturally occurring and somewhat unpredictable. As such, transformational advancement in energy storage to create a more resilient grid is the only practical way to harness these resources to match the oncoming tidal wave of demand for electrified power.

Further, the world is moving toward an all-electric automotive industry and a greater proliferation of electronics. However, this electric transition requires better batteries in order to meet market expectations and to accelerate this proliferation. The perfect storm of energy demand is upon us, requiring immediate energy storage advances so everything that can be powered by batteries is powered by rechargeable batteries.

As more players enter the ever-expanding lithium-ion (li-ion) battery markets, companies face unexpected hurdles to reach the level of scale that leaders like Tesla have achieved. Even as Texas faced one of the worst energy disruptions the state has ever seen in February 2021, the U.S. automaker continued its march toward production and just weeks later announced its Gigafactory would be built in Austin. Disruptions happen. As we’ve seen from 2020-2021, Covid-19 has disrupted not only our way of life but also our global supply chains. The pandemic has acted as a forcing mechanism for countries to reprioritize domestic supply chains to meet the demand for li-ion batteries. This newfound prioritization for domestic battery supply chains is driven by growing demand for reliable and better performing electrified goods across all sectors.

Successfully supplying this market demand without domestic supply chains is a daunting task that faces often unpredictable variables, including uncertain access to the finite resources of fossil fuels, unforeseen global social-political conflicts that spike energy costs, global trade, and most importantly, climate change variables that continue by the season. Domestic supply chains are now a necessity.

The below Wood Mackenzie chart demonstrates the growth forecast of battery powered goods, highlighting the importance of domestic supply chains to reliably meet this demand.

World Li-ion Battery Use by Market, 2019-2029 (GWh)

Wood Mackenzie. From: Lithium-ion Batteries: Outlook to 2029. (2021).

The near exponential growth in electrification demand is driven by entire industries evolving toward electrification, notably in the automotive industry. As has been seen in everything from Superbowl commercials to President Biden’s infrastructure plan, an all-electric future with electric vehicles as the norm is on the horizon — the evidence for this paradigm shift is in the industry growth curve and consumer behavior for and around EVs.

EV adoption is accelerating at an incredible rate. According to online automotive resources provider Edmunds, EV sales could hit a record high this year, with EV sales compared to all retail sales expected to grow over 30% in 2020 compared to 2021. The math is simple to follow. This number will continue to grow year over year. As EVs continue to improve mileage, develop extreme fast charging in minutes instead of hours, and achieve cost parity with internal combustion engines (ICEs), EVs will increasingly replace most commercial vehicles running on fossil fuels over the next decade, as is demonstrated in the following two Roskill predictive charts.

Forecast Sales of Electric Vehicles, 2019-2029 (GWh)

Wood Mackenzie. From: Lithium-ion Batteries: Outlook to 2029. (2021).

Global Penetration Rate of Electric Passenger Vehicles, 2010-2029 (% of Sales)

Wood Mackenzie. From: Lithium-ion Batteries: Outlook to 2029. (2021).

Indicators of the all-electric future surround us. California, the EU, and other governments will phase out the sale of gasoline-powered cars and trucks by 2035 and President Biden is planning to transition federal fleets to all-electric vehicles. Space exploration and research will become more common; robots will be used for personal and commercial use; the proliferation of artificial intelligence (AI) and mobile/wearable tech will continue to see exponential growth. Powered by consumer demand, technological advancements, government mandates, and environmental variables, it’s clear that the next ten years will see warp-speed growth into the electrification of everything era. Unfortunately li-ion battery chemistries using graphite anodes currently power all things electric and have reached the ceiling for their potential and no longer meet market expectations, requiring a deep rethink of li-ion chemistry.

To date, energy storage advancements have been incremental for li-ion, resulting in a potential performance that has topped out, approaching the practical limit of current state batteries. However, to meet the forecasted demand, as well as the realities of modern industry, incremental change doesn’t work anymore. We need to shift current li-ion chemestries toward energy storage technologies with better performance: lasting longer (high energy density), charging faster (eliminating charge anxiety), having a lower cost (ensuring widespread adoption), and achieving all of this today, not in five years (immediate scale with drop-in solutions).

While big advances have been made in lithium-ion battery technology, the “it” chemistry platform underlying nearly all things electric, the biggest hurdle to achieving the true goal persists—a transformational drop-in li-ion battery technology that helps bring EVs to cost parity with internal combustion engine cars and enables a new era of efficiency and power for all electronics. The electrification of everything “it” chemistry lies with silicon-based anodes, immediately turning today’s li-ion batteries into lithium-silicon batteries.

Silicon-based anodes that can drop into li-ion chemistry to create lithium-silicon batteries will help to break through these hurdles and unlock an electrified future with longer lasting, better performing electronics, electric transportation, electric flight, space travel, and much more. Lithium-silicon batteries have high density, extreme fast charging, and are the right price. The need to transition to a new form of lithium battery is critical for meeting the demands of today and the needs of tomorrow.

Transforming li-ion batteries into lithium-silicon batteries, for what is a tiny change in cost, delivers a huge step change in performance. The following chart highlights the tremendous growth and usage of li-ion batteries we’ve seen across sectors, highlighting why transformational drop-in solutions for li-ion batteries are so important.

World: Li-ion Battery Use by Market, 2000-2019 (GWh)

Wood Mackenzie. From: Lithium-ion Batteries: Outlook to 2029. (2021).

Switching From Lithium-Ion Batteries To Lithium-Silicon Batteries

There are myriad paths to innovate lithium battery technology and not all the approaches envisioned are stable, commercially viable/scalable, produce improvements across all battery metrics, and/or are cost-effective. To date, the anode side of the li-ion battery cell has seen less innovation in adapting li-ion batteries to different needs than the cathode. However, anode innovation is where step-change transformation will take place. As of now, graphite has been the only reliable solution for the anode. Unfortunately, graphite as a stand-alone anode has significant limitations to its energy density and charge times that hinder the advancement of electric technologies.

To meet the growing tidal wave of demand for better lithium-ion batteries, global battery manufacturers need more than incremental improvements around the performance of graphite. They need a drop-in replacement that clearly exceeds the potential of graphite.

A long-standing goal for anode innovation with lithium batteries has been to leverage silicon as an active material inside of the anode, creating a lithium-silicon battery. Lithium-silicon batteries have the potential to hold huge amounts of lithium ions due to silicon’s 10x higher capacity than graphite. This quickly translates in cost parity for EVs and creates smaller, better lithium batteries for all electronics and energy storage. The idea is that a silicon-based replacement for graphite not only gives a massive boost to lithium’s performance and energy density within the battery but it also seamlessly fits into existing manufacturing processes.

By simply swapping out existing graphite anode material, drop-in-ready silicon-based technologies help minimize switching costs for manufacturing. They also eliminate the need for what could potentially be multi-billion-dollar manufacturing changes across different industries, and/or net new battery designs.

These new and improved silicon-based anode materials can immediately integrate into existing battery cell manufacturing lines to create better-performing batteries today, with no additional requirements for implementation at the cell level. True drop-in power provides three important characteristics:

- Reduced reformulation work required during the initial validation and product development phases

- Zero CapEx needed for retrofitting on the manufacturing line

- Significant reduction in time to market for new products

Drop-in technology is a critical step to prove to the industry at large, customers, and financial markets, that a technology is easily manufacturable at scale and at a digestible cost from the first factory to all subsequent production facilities. The exciting potential of silicon-based battery anode materials, like our SCC55™, that are drop-in ready and manufactured at industrial scale, is that they create a step-change in what’s possible with energy storage. Lithium-silicon batteries move the world toward the electrification of everything because they are significantly more highly performing than li-ion batteries using graphite across all performance metrics. Lithium-silicon batteries have:

- Higher energy density,

- are faster charging than li-ion batteries using graphite, while

- having comparable stability to graphite over 1000 deep-discharge cycles, allowing us to innovate things that we haven’t been able to imagine before.

The basic reason for these performance improvements is simple—silicon can hold many more lithium atoms than graphite. One silicon atom absorbs four lithium atoms, whereas six atoms of graphite can only accommodate one lithium atom. Thus, silicon can hold 10x more lithium by weight than graphite. This allows for a much smaller anode in the cell, opening up more space for more cathode material (more lithium). It is the cathode that brings this initial lithium into the battery and so the more room enabled for the cathode – the more energy density possible. Replacing the low capacity graphite anode with a high capacity silicon anode delivers a revolutionary step-change in performance relative to the rate of battery improvement over the last 20 years.

The challenge with silicon chemistry up until this point has been that lithium ions inside of silicon can cause 3x expansion of the silicon, producing obvious problems of stability and mechanical stresses for batteries. If the silicon swelling problem could be solved for silicon-based anodes, the long-standing desire to use silicon would be achieved, helping usher in a new era of energy storage across sectors.

Group14 has solved the swelling challenge by creating a nanocarbon scaffold that acts as a host material for silicon and stabilizes the silicon during the lithiation (charging) and delithiation (discharging) processes. This innovation delivers greatly improved energy density and cycle efficiency for the lithium battery cells it lives in. When adopted, the lithium-silicon battery will replace the current lithium-ion battery, thus enabling the true electrification of everything today—not tomorrow.

Group14, Silicon-Carbon Anodes, and The Electrification of Everything

Replacing our energy dependence on the finite supply of fossil fuels as well as tackling climate change (emissions) are complicated undertakings. There’s a good rule of thumb for how to get started: electrify everything and electrify fast. From day one, we knew how critical it was to intentionally build up an advanced battery materials company with the right footholds to scale quickly and ensure SCC55™ bridges the chasm from lab to market at commercial scale as quickly as possible to meet global demand for the electrification of everything. Our stable silicon-carbon composite anode (SCC55™) has five times the capacity of graphite and affords up to 50% more energy density than conventional graphite for lithium battery anodes. It’s unique carbon-based scaffolding keeps silicon in the most ideal form–amorphous, nano-sized, and carbon-encased. SCC55™ dramatically increases energy density and radically improves battery charge times.

Depiction of SCC55™ at Nanoscale

The SCC55™ carbon scaffold’s integrated intra-particle void space was engineered to prevent silicon expansion. The ability to stabilize or suppress the expansion of silicon enables a best-in-class anode material that exhibits outstanding first cycle efficiency, less electrolyte degradation, and long cycle life that’s performance is head and shoulders above other anode materials across the full cycle life of a battery.

However, what makes our SCC55™ carbon structure truly special is control: our control over the scaffold structure allows us to tune silicon properties for different applications more easily and safely because the nanosilicon is contained in a micronized carbon as opposed to unbound nanoparticles. Additionally, the porous carbon structures’ inherent tunability means we can meet different silicon content needs with relative ease, adjusting for capacity and cycle stability control. Furthermore, having a carbon-silicon interface allows for good electronic conductivity, which is important for rate capability (an ability to generate a considerable amount of power without suffering from voltage loss).

It’s important to also note that carbon modifications are inherently scalable, enabling us to address different customer needs rapidly with SCC55™ which is optimized to fully replace or blend with incumbent graphites as a drop-in ready solution for today’s lithium-silicon batteries.

SCC55™ Anode Achieves Energy Density Projected to 1,150 Wh/l

Since SCC55™ is drop-in ready today, it enables an immediate transition from lithium-ion battery technologies to a new paradigm of highly efficient lithium-silicon batteries. Our company is able to meet demand for this battery transition because we designed our product and processes to be at an industrial-scale through the usage of conventional manufacturing equipment, using a modular commercial approach that can be replicated and scaled rapidly at any location (discussed further in our next whitepaper). We recognize the urgency for electrifying everything, which is why we also streamlined the process of making our silicon-carbon composite anode down to two patented process steps, allowing us to meet the commercial demand for advanced battery materials with ease.

The commercial scalability of Group14 technology is especially significant because SCC55™ meets the threshold for dollars per kilowatt hour for EVs, enabling cost parity for electric vehicles today—years faster than any other offering on the market. We’re prepared to address EV demand right now.

EV Cost Parity with SCC55™

We are living during unprecedented times for innovations that will replace energy sources and technologies reliant on fossil fuels, greening the grid, and providing a new era of capabilities that electrify the world across sectors (automotive, consumer electronics, manufacturing, and aerospace). However, many of these innovations and their promises are only as good as the batteries powering them. The ask coming from each of these industries and from battery manufacturers is seemingly simple—make their batteries more powerful without making them more expensive. But the scale of this ask amounts to a tidal wave of demand and manufacturing for new-to-world deep technology innovation the battery industry has not seen.

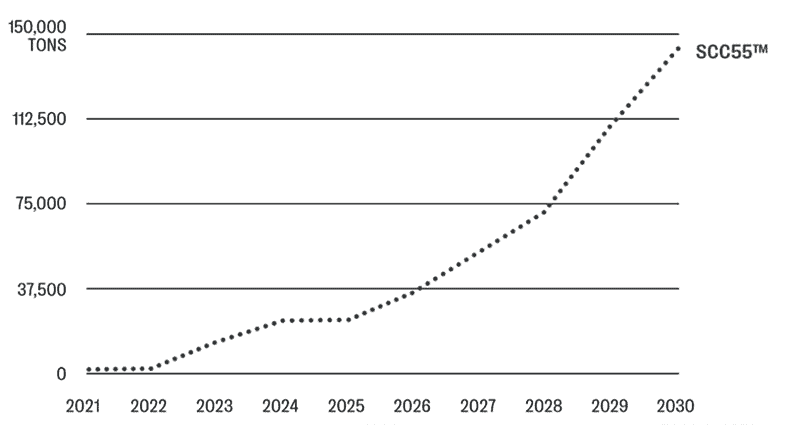

We’re meeting this electrification of everything demand by accelerating our throughput of SCC55™ and scaling our total number of BAM factories. Further, to help curtail supply chain turbulence, we’re building another BAM factory in South Korea, via a joint venture (JV) with SK materials, a subsidiary of SK Group, one of the global leaders in electronics, digital displays, and semiconductor devices.

The volatility of the global supply chain poses significant challenges for battery powered industries such as consumer electronics, electric vehicles, medical devices, and more (threatening the world’s ability to electrify everything quickly). To mitigate supply chain disruptions, our JV opens up the capability for dual sourcing of our lithium-silicon technology both from South Korea and domestically, radically shortening our timeline to meet demand as well as strengthening our capability to reliably deliver our patented lithium-silicon battery technology to customers immediately.

In other words, demand for next generation lithium batteries that eliminate range anxiety are tremendous and accelerating quickly, but considerable hurdles still remain—namely commercial scale and global supply chain volatility. We foresaw these challenges when we built our business and took precautions to circumvent them, ensuring we could commercially manufacture and distribute our advanced battery materials to fulfill our vision to electrify the world today.

It’s important to note that we believe that the electrification of everything era is a challenge faced best by a team of innovators and collaborators and not in the hands of the few or any single provider. We’re excited to see all of the amazing advancements taking place in energy storage from brilliant companies and unconventional thinkers around the world, and we’re enthused to be one of them. We all share the same collaborative vision to improve energy storage fast and to electrify everything.

Group14’s dedication to meeting the battery demands of today through lithium-silicon battery innovation and scalable commercial manufacturing processes are what differentiates us and makes us a reliable partner. We’re transitioning the energy storage industry today so that one day soon, we’ll wake up to an all-electric world.

SCC55™ Scale and Production Timeline

We hope that this paper helps our stakeholders better understand the broader lithium-silicon battery landscape and sheds light on Group14’s industry-leading silicon-carbon composite anode, SCC55™.

Our next whitepaper will go into greater detail about how we have solved the challenge of rapid commercial manufacturing scale while keeping CapEx down for our partners.