Blog|06.23.25

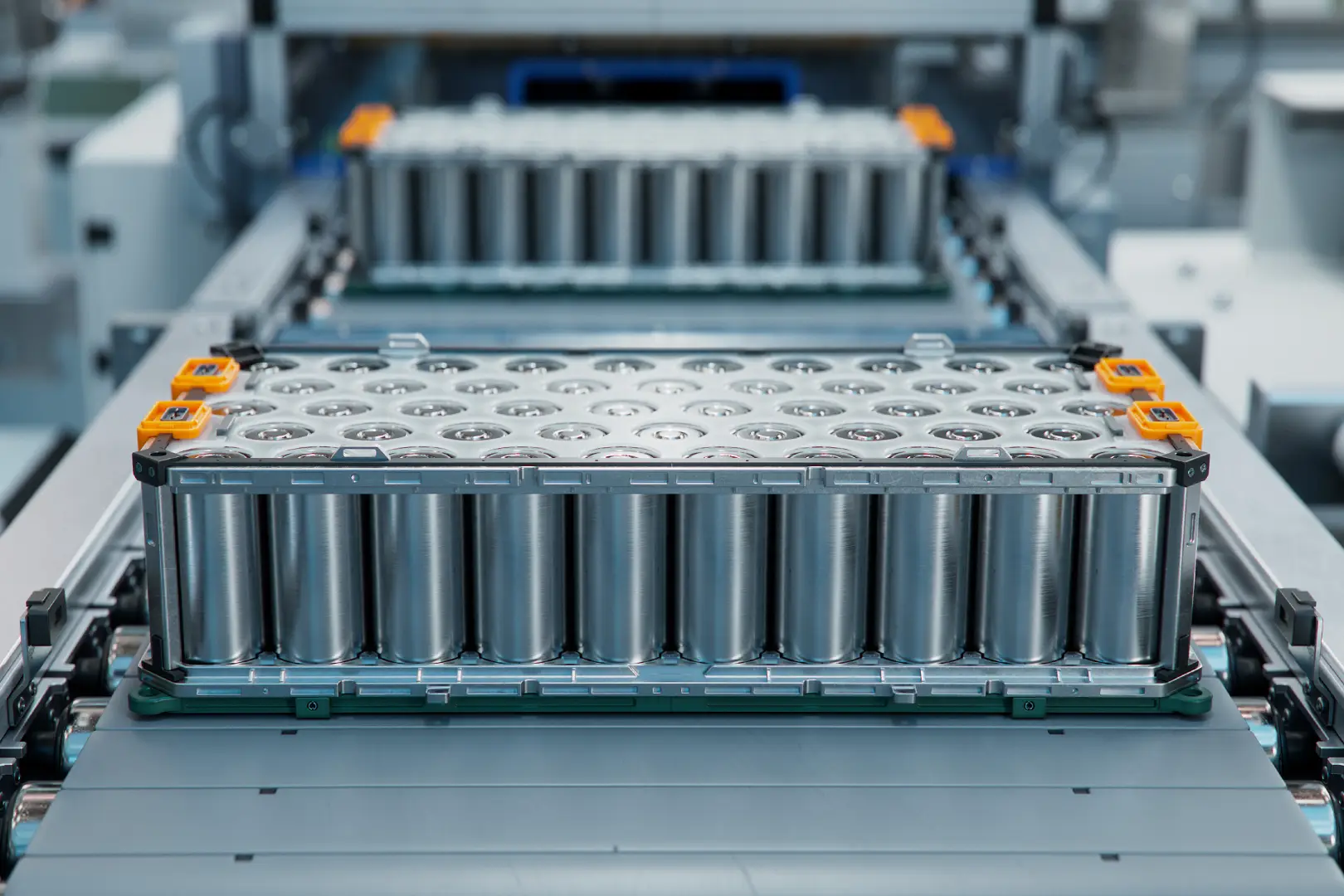

Apple IPhone Supplier TDK Rolls Out New Batteries to Keep Pace With AI

Bloomberg: TDK Corp. plans to mass-produce advanced silicon-anode batteries with 15% higher energy density in 2025, addressing rising AI-powered device demands. These batteries enable faster EV charging and enhanced smartphone performance. Partnering with Group14 Technologies and ATL, TDK is leveraging rapid production capabilities despite concerns about supply limitations. Growth is expected incrementally, as silicon battery adoption expands.