From the smartphone in your pocket to the servers crunching AI models at hyperscale, our tech-driven world is increasingly reliant on rechargeable energy. For decades, advances to batteries have come largely from one side of the equation: the cathode. Built from materials like cobalt, nickel, and manganese, the cathode has quietly dictated how much energy a battery can store, how quickly it can charge, and how long it can last. Progress meant optimizing these materials to achieve incremental performance improvements over time.

But that strategy is reaching its limits. As manufacturers squeeze the last gains from cathode chemistries, the focus is shifting to the other half of the battery: the anode. New anode materials are breaking through long-standing performance ceilings on lithium-ion batteries, delivering major leaps in energy density and charge time. For the first time in over 30 years, battery developers are no longer limited by the constraints of the cathode – they can now engineer the cell from both sides. The results are already reshaping what’s possible across consumer electronics, electric vehicles, and grid-scale energy systems.

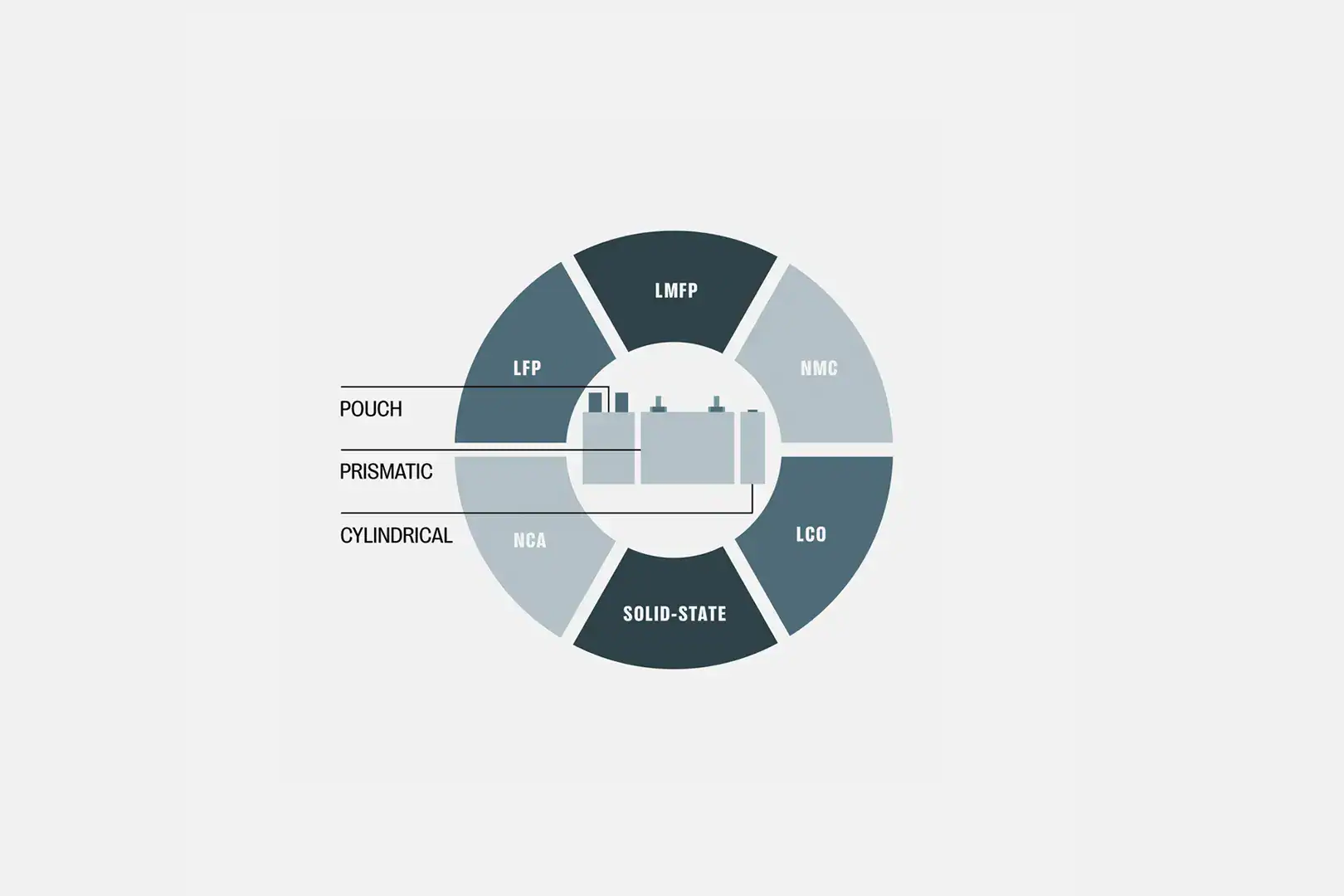

Why Compatibility Still Reigns: NMC, NCA, LFP, LCO, and the Rise of LMFP

Every battery is a balancing act between chemistry, cost, and performance. That’s why OEMs choose different cathode materials based on the job at hand. BMW mostly sticks with Nickel Manganese Cobalt Oxide (NMC) for its high-energy density, while GM and Ford are transitioning models to Lithium Iron Phosphate (LFP). Tesla mixes things up, using Nickel Cobalt Aluminum Oxide (NCA) for its high-performance vehicles and LFP for cost-effective, mass-market models. Consumer electronics still lean on Lithium Cobalt Oxide (LCO) thanks to its higher volumetric energy density and technological maturity.

The challenge? Every cathode chemistry comes with tradeoffs.

The solution? Anodes that are designed to work with all cathodes. Unlike lithium-metal anodes, Group14’s drop-in silicon-carbon composite, SCC55®, is compatible with all cathode chemistries, unlocking major upgrades within the same manufacturing structure as conventional lithium-ion cells.

In EVs, pairing SCC55 with an LFP cathode is a performance game-changer. LFP has always been the safer, lower-cost option, at the expense of energy density. Add silicon into the mix and suddenly you’re talking 50% higher energy density, meaning longer range and radically faster charging.

The LMFP Moment: What’s Next in Cathode Chemistry

Cathode innovation isn’t done yet. Lithium manganese iron phosphate (LMFP) is gaining attention for its higher voltage, and thus higher energy density, at similar cost to LFP. Essentially, LFP with more punch.

But again, it’s the anode that unlocks LMFP’s full potential. Paired with SCC55, LMFP batteries are already showing promise in reducing charge time, increasing power capability, and increasing range, some of the most critical metrics for EVs.

As LMFP edges closer to mainstream adoption, high-performance silicon anodes are the key to pushing LMFP to near NCM-type performance levels.

Looking Ahead: Silicon in a Solid-State World

The future of batteries doesn’t stop at lithium-ion. Solid-state batteries are on the horizon, promising even higher energy densities and improved safety. But these next-gen systems face some key challenges, namely interface instability, low power output, and manufacturing hurdles that are yet to be resolved.

Here’s where silicon steps in again. Though SCC55 was built for today’s liquid-based lithium-ion cells, its ability to deliver high capacity and stability also makes it a natural fit for solid-state designs. Early tests show that it could help bridge solid-state’s gap from prototype to real-world performance.

Silicon Batteries: a Solution for Today, and Tomorrow

The energy demands of the next decade are staggering, as AI data centers, EV fleets, smart infrastructure, and electrified homes are increasingly integrated into our daily lives. All of it depends on improvements to our rechargeable energy solutions.

That’s why the battery world is betting big on silicon. Its versatility, scalability, and breakthrough performance are no longer just theoretical. They’re showing up in products on the market today.

This is just the beginning. In the years ahead, expect to see nearly every rechargeable product – from consumer electronics, to transportation, to mobile storage – running on the power of silicon.